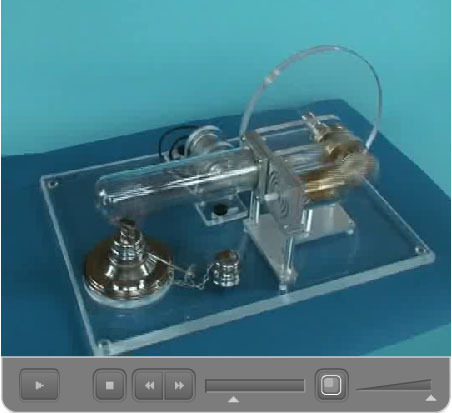

The simple-functioning Stirling Motor has a piston in the parallel-configuration and a balanced and quiet operation at over 1000 U/min. In order to visually monitor any of the movements in the apparatus, an emphasis was put on operational transparency was designed into GT04. In accordance with this consideration, the pressurization cylinder, displacement cylinder, and displacing piston consist of a specially designated glass, and the flywheel and gear case of Plexiglas.

The crankshaft is mounted with ball bearings and consists of hardened steel, and the connecting rod and crank of a wear-resistant plastic. Due to the constitution of this units components, its operation is very quiet and maintenance-free with a performance of ca. 1.5 mechanical Watts.

This model is mounted onto a ground plane, having a large, transparent flywheel and a hardened steel crankshaft with ball bearings. Both cylinder and displacing pistons consist of hear resistant specially designated glass. The connecting rod and crank are made of wear-resistant plastic.

Watch Video:

Accessories Included with Your Order:

Ground plane: 300 x 220 mm

Flywheel: Ø 140 mm

Spirit Lamp with Adjustable Wick

Motor/Generator Unit with Belt

Technical Data:

Performance of the Motor: ca. 1.5 W

Rotations per Minute without Resistance: ca. 1000/min

Volume: 32 cm³ - 44 cm³

Steadfast and Maintenance-free Operation:

The crank web and crank pin are both inset with Ball Bearing, hardened, and polished. The discharge shaft is also hardened and polished. The triangular transmission, cross-bar, and guidance bar consist of an extremely wear resistant, attenuated plastic. The crank case, connecting tube, as well as the cylinder cap consist of a corrosion-resistant aluminum alloy, each having been polished multiple times.

Transparency:

To ensure both safety of element function and visualization of the unit?s mode of action, the cylinders and working piston are constituted of a specific safety glass, while the gearbox and flywheel consist of Plexiglas.

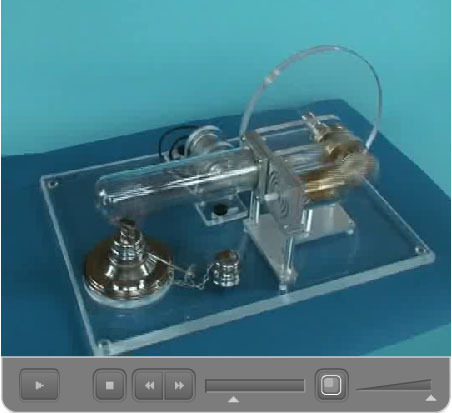

Motor/Generator Unit

Unit transforms mechanical energy from the Stirling motor into electrical energy, whereby a light bulb (E 10 socket) is illuminated via an electrical conduction box (max. 12 V), and the operation of the Stirling motors as a heat pump or as cryopump (with belt).

Production of Electric Energy:

The transformation of thermal energy into mechanical, then electric energy is demonstrated impressively via the motor / generator unit integrated into the pedestal. A light bulb is illuminated by the operation of the generator.

Operation as a Cooling Unit and Heat Pump:

To elaborate on the conversion of thermodynamic processes, the Stirling motor can be powered by its electric motor to change its mechanic torque, serving to remove thermal energy, e.g. produce cold, in one direction and to produce heat by operation in the opposite direction.

Displacement Cylinder (for School Design, note price difference)

The determination of the operating temperature and the temperature difference with two Instrumentation Supports with bored holes (Ø 1 mm) for the mounting of thermal detection elements.

Ground plane:

The ground plane is composed of Plexiglas, the upper edges of which are facetted. Secure positioning of the unit is secured by the vibration dampening, skid-resistant rubber knobs on the undersurface of the ground plane.

Watch Video:

Video GT04 working with Motor / Generator - Unit for browser view.

Video GT04 working with Motor / Generator - Unit in high quallity for Download (24MB)